When robots learn to speak the same language: The new era of industrial interoperability

For years, industrial robotics evolved in closed environments: each manufacturer developed its own languages, architectures, and control protocols. This approach, while enabling significant advances in automation, created a structural problem—fragmentation—that limits scalability and makes it difficult to integrate heterogeneous equipment within the same plant or production line.

Today, that reality is changing. Robotics is no longer a promise; it has become an essential component of daily operations in factories, logistics environments, and energy facilities. However, the rapid growth of robots and autonomous vehicles has brought a new challenge: interoperability.

In ecosystems where equipment from different manufacturers must work side by side, each with its own software, interface, and communication system, companies face increasing complexity when coordinating tasks, exchanging data, or ensuring operational safety. The lack of a common language among robots from different suppliers forces organizations to deploy partial or vendor-dependent solutions, with high integration and maintenance costs.

Toward a common language for robots

As the sector matures, open standards that promote cooperation among systems are gaining ground. Frameworks like Open-RMF, driven by the Open Source Robotics Foundation, and VDA5050, developed by the German Association of the Automotive Industry, are laying the foundations for different types of robots to share information, plan joint routes, and execute missions in a coordinated, safe way.

Added to this is the integration of 5G, which enables true convergence between the IT and OT worlds. This low-latency, high-reliability connection opens the door to real-time monitoring and control, an essential requirement for critical industrial environments.

The intelligent orchestration layer

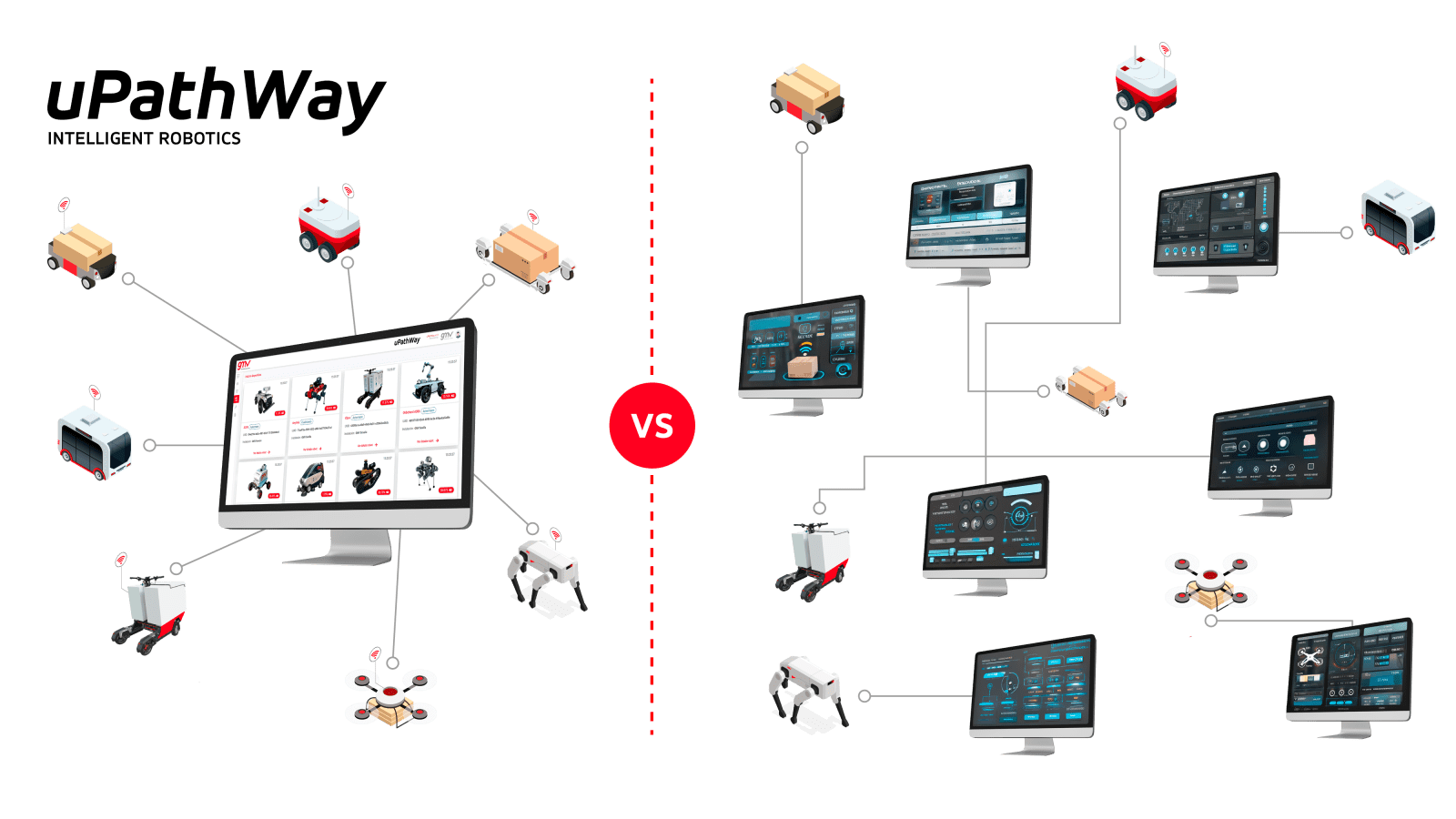

In this context, a need has emerged for an orchestration layer that acts as a bridge between technologies, manufacturers, and systems. This is where solutions like uPathWay become especially relevant, offering an approach centered on robotic interoperability.

uPathWay makes it possible to manage and monitor mixed fleets from a single platform, serving as a unifying core that integrates robots and autonomous vehicles from different manufacturers. Its open architecture streamlines mission planning, task coordination, and remote supervision through advanced AI-driven tools designed to optimize routes, detect anomalies, and analyze performance in real time.

AI-driven robots: The ideal teammates

The combination of robotics and artificial intelligence is transforming how we understand automation. Robots are no longer limited to repetitive tasks: they are now intelligent agents capable of collaborating, learning from their surroundings, and operating autonomously in complex or high-risk environments.

From inspecting photovoltaic plants to overseeing offshore platforms or monitoring production lines, interoperability is what allows all these systems to work together in a coordinated, efficient, and safe way.

We are therefore entering a stage of technological maturity in which robotics is no longer measured solely in terms of hardware, but in terms of connectivity, collaboration, and shared intelligence. Interoperability will be the key to unlocking its full potential and building factories, plants, and industrial environments that are truly autonomous and resilient.

Author: Eric Polvorosa